My painter, fairing crew boss, and chief Boatamalan informs me that there are exactly seven “paint days” remaining before our Roamer 46 is painted with the shiny, non-skid and accent stripes…top to bottom.

Seven paint days… After five years, I’m ready for it.

Of course, since we only work on the boat on weekends seven paint days works out to be about a month. So, it looks like we’re not going to make the end-of-May 2013 target, but we’re not far off. Before the paint days can begin, though, we’ve got to finish up the priming. And the last section of the boat that remains unprimed is the new (in 2008) aluminum aft deck enclosure.

Last weekend, we got ‘er done.

It was nice to see the boat in natural sunlight while I was transforming Tent Model IX once again. The aluminum to FRP hardtop fillets turned out nice.

This vertical welded seam creates a subtle but hard corner on the outside of the aft enclosure panel.

Even with the seam weld ground down and the panel sanded, there still is a bump you can easily feel.

If you can feel a bump, it’ll really stand out when it’s painted with “the shiny” AwlCraft 2000 Matterhorn White.

I’ve found that US Composites 635 epoxy and their 4:1 hardener (their fastest one) takes a lot more time to cure than West System. Production time costs, so at this late stage of the game we’ve switched to West System and their fast hardener so we can mix up epoxy + cabosil (40%) + 3m microballoons (60%) fairing compound, apply it and sand it just an hour or two later.

Another lesson learned: buying a 55-gallon barrel of West System at the start of this project would have been significantly cheaper and faster than ordering US Composites in multi-gallon kits. If I knew when the project started what I know now…

All of those nooks and crannies are a PITA! Once the sanding was done, I hit all of the corners, seams and welds with a wire wheel on my Makita sander. Meanwhile, the guys longboarded the fairing compound we applied around the welded seam on the aft panel.

With all of the longboarding, sanding and wire brushing done, we applied Alumaprep and then Alodine.

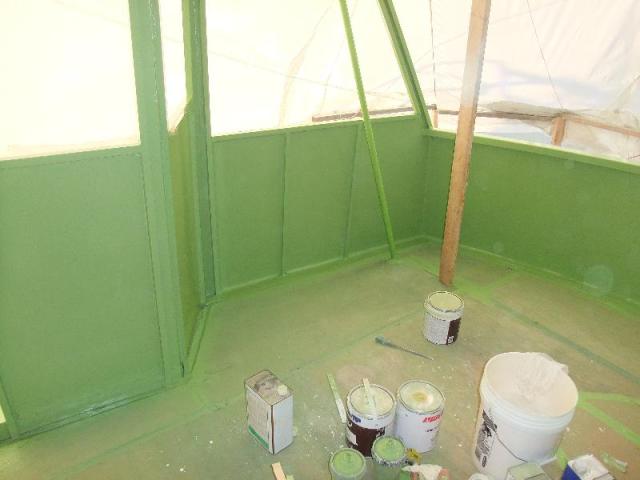

Next came the Awl Grip Max Cor aluminum primer.

The vertical line of Max Cor is where just a hint of a weld high spot remained in the aluminum, but the guys faired it out so well that I can’t feel any high spot at all.

Max Cor is the replacement for the previous Awl Grip aluminum primer that was available when we first got the boat. The old stuff was yellow and didn’t stink anywhere near as bad as this new stuff, which is also 25% more expensive. Everybody in the tent had space suits, full face masks and VOC filters on, and the exhaust fan filters turned green in no time!

The welds for the aft entryway are on the inside of the panels, which leaves an exposed seam without welds on the vertical surfaces you see here. We cut the door out after welding it all together, so the door and the opening would hold their natural, curved shape. Welding the exposed seams on the vertical threshold pieces would put a lot more heat into the panels and, because it’s aluminum, might cause warping — the curved door that fits the curved panel might not anymore.

We don’t anticipate any movement on the seams, but just putting fairing compound into a seam crack would just beg for the compound to crack in the future. So, we mixed up some West System thickened with 404 adhesive and wetted out the aluminum before applying wetted out 12oz fiberglass cloth over the seams in both vertical threshold panels. The 404 keeps the fiberglass firmly attached to the aluminum, and the fiberglass will not crack the way filler might.

The challenge was–how to apply Alumaprep and Alodine (both acids) and water to the bare aluminum without having any of the liquids wick in between the stitch welded aft enclosure framing and exterior panels. If any liquids got into the seams, there’s no way we could prime within the window stipulated on the Awl Grip product labels. After talking about tape and a few other ideas, we settled on mixing up more homemade epoxy fairing compound and putting fillets at every joint and seam. It was time consuming, but the fillets preclude liquids from entering the seams, and the primer film is now continuous over the entire aluminum surface, inside and out. Since aluminum oxide can travel very far under primer when there’s a break in the film, this approach should ensure a very long life sans corrosion for this enclosure and its paint job.

After two coats of Max Cor, we waited 1-1/2 hours, then broke out the Awl Quik and a five-gallon pressure pot paint rig.

The fairing crew from Weaver Boatworks that’s moonlighting on weekends doing my boat…they sure do nice work.

This is turning out just like I envisioned with my cardboard mockups in 2008!

And with that, the aft enclosure was in primer!

I’m all giddy! 🙂

Next up on our 1969 Chris Craft Roamer 46 Refit: Fillets & Final Touches on the Aft Deck Enclosure

I have been following this story since the begining and i am truly amazed by the in depth story! I am looking at buying a 41 foot 1968 Hatteras and I am expecting to remodel this boat and trying to figure out the $$ is the hard part. I am going to try to do the work myself and it will take years for me to do what I want with it. But my lid on my paint can and brush are lifted in the air to you!

Ron

Thanks!

I like those 41 Hatts. There are two of them at my marina–both are Detroit 853-powered boats. The $$$ is definitely a hard part. We could have saved a lot by cutting corners or, in some cases, by just doing things differently. It definitely would have been cheaper to repower with modern gas engines than the Cummins 450 Diamonds. Stripping the interior paint and repainting would have been cheaper than an interior refit. But then, if we took that approach it would probably worked out best to just buy one that somebody had taken care of. And that brings us back to the fact that if we’d taken that approach, we wouldn’t have our dream boat in the end. I do have to agree with that old wisdom, though–whatever your worst-case estimate is for the refit budget…double it, and you won’t be too far off.

Cheers,

Q

Looking great Q! Will my bunk be ready in August? Bermuda? I’ll be making a trip back east some time and gotta get the tour! Next on to the Z!!!

There’s plenty of room for you on MV Honey, my Commander 42. I’ve also got some cans of Cetol and a brush you can use to freshen up the toe rail. 😉

Q

Nice going there, Q! Do you have a name picked out for this labour of love, yet? ;0)

I’m too tired to think of names, M! The working title has been “The Roamer,” but then “Engines and a Paint Job” has a nice, historical ring to it. 🙂

Q

Outstanding work. Few realize how much determination and sweat goes into such a job – but then again, few get to bask in the reflected glory. Its waiting for you.

Cheers!

-Eric

Thanks, E! I was reading an article in a yachting magazine recently about a trend in megayacht toward refits over new builds. Turns out, something about the classics makes certain people happier than whatever is coming out of the factories new these days. Maybe us old Roamer and Commander crazies were onto something after all, even if we don’t have the $$$ to just write a check and have somebody else do it.

Personally…I think I’d still want to be hands-on even if I was loaded like…well…whoever’s really loaded these days.

Cheers,

Q

I remember the anticipation as we faired and painted our 41 regal, and the feeling that WOW we are in the home stretch of our 3 year project, Our task was miniscule in comparison…

I look forward to every posting you make, and feel honored that you have shared your project with us.

Thanks, Mark. I really appreciate the kudos. “Man cannot live on Awl Grip products alone” or something like that. Supportive comments really do help.

Cheers,

Q

Impressive and damn fine work.

Thanks, Craig!